PRTG Manual: EXE/Script Advanced Sensor

The EXE/Script Advanced sensor runs an executable file (.exe) or a script (batch file, VBScript, PowerShell) on the probe system. This option is available as part of the PRTG API.

The return value of this sensor must be valid Extensible Markup Language (XML) or JavaScript Object Notation (JSON).

If you want to execute a custom Windows Management Instrumentation Query Language (WQL) script, use the WMI Custom sensor.

For a detailed list and descriptions of the channels that this sensor can show, see section Channel List.

- Dutch: EXE/Script Geavanceerd

- French: Script/EXE avancé

- German: Programm/Skript (Erweitert)

- Japanese: EXE/スクリプト(アドバンスト)

- Portuguese: EXE/Script avançado

- Russian: Расширенный сенсор EXE/скрипта

- Simplified Chinese: 高级 EXE/脚本

- Spanish: EXE/Script (avanzado)

Consider the following remarks and requirements for this sensor:

Remark |

Description |

|---|---|

Remote PowerShell |

This sensor requires that Remote PowerShell is enabled on the target system and PowerShell 3.0 on both the probe system and the target system.

|

File storage |

The sensor requires the executable or script file to be stored on the probe system. In a cluster, copy the file to every cluster node. |

Microsoft .NET Framework |

This sensor requires .NET 4.7.2 or later from Microsoft on the probe system. In a cluster, install it on every cluster node.

|

Windows Server |

We recommend Windows Server 2016 on the probe system for best performance of this sensor. |

Channels |

This sensor does not officially support more than 50 channels. |

IPv6 |

This sensor supports IPv6. |

Performance impact |

This sensor has a medium performance impact. |

Knowledge Base |

|

Hosted probe |

|

Custom scripts on Windows Consumer Editions |

To run a script in PRTG on this sensor, you have to open Windows PowerShell with administrator rights and enter the following command: powershell.exe Set-ExecutionPolicy -ExecutionPolicy RemoteSigned -Scope LocalMachine |

The sensor has the following default tags that are automatically predefined in the sensor's settings when you add the sensor:

- xmlexesensor

For more information about basic sensor settings, see section Sensor Settings.

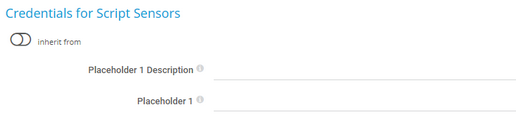

Credentials for Script Sensors

Click ![]() to interrupt the inheritance.

to interrupt the inheritance.

Setting |

Description |

|---|---|

Placeholder 1 Description |

Enter a description for Placeholder 1, for example information about the purpose or content of the placeholder. |

Placeholder 1 |

Enter a value for the placeholder. PRTG inserts the value for the script execution if you add %scriptplaceholder1 in the argument list. PRTG does not display the value in the sensor log or the sensor's settings. |

Placeholder 2 Description |

Enter a description for Placeholder 2, for example information about the purpose or content of the placeholder. |

Placeholder 2 |

Enter a value for the placeholder. PRTG inserts the value for the script execution if you add %scriptplaceholder2 in the argument list. PRTG does not display the value in the sensor log or the sensor's settings. |

Placeholder 3 Description |

Enter a description for Placeholder 3, for example information about the purpose or content of the placeholder. |

Placeholder 3 |

Enter a value for the placeholder. PRTG inserts the value for the script execution if you add %scriptplaceholder3 in the argument list. PRTG does not display the value in the sensor log or the sensor's settings. |

Placeholder 4 Description |

Enter a description for Placeholder 4, for example information about the purpose or content of the placeholder. |

Placeholder 4 |

Enter a value for the placeholder. PRTG inserts the value for the script execution if you add %scriptplaceholder4 in the argument list. PRTG does not display the value in the sensor log or the sensor's settings. |

Placeholder 5 Description |

Enter a description for Placeholder 5, for example information about the purpose or content of the placeholder. |

Placeholder 5 |

Enter a value for the placeholder. PRTG inserts the value for the script execution if you add %scriptplaceholder5 in the argument list. PRTG does not display the value in the sensor log or the sensor's settings. |

Setting |

Description |

|---|---|

EXE/Script |

Select an executable file from the list. The sensor executes it with every scanning interval. The list contains all files in the corresponding \Custom Sensors\EXE subfolder of the PRTG program directory on the probe system. For a file to appear in this list, store the file ending in .bat, .cmd, .exe, .ps1, or .vbs into this subfolder.

|

Parameters |

If your executable or script file catches command-line parameters, you can define them here. You can use placeholders as well. Enter a string or leave the field empty.

|

Environment |

Select whether PRTG command-line parameters are also available as environment parameters:

|

Security Context |

Define the Windows user account that the sensor uses to run the executable or script file:

|

Mutex Name |

Define a mutual exclusion (mutex) name for the process. Enter a string or leave the field empty.

|

Timeout (Sec.) |

Enter a timeout in seconds for the request. Enter an integer. The maximum timeout value is 900 seconds (15 minutes).

|

Result Handling |

Define what the sensor does with the result that the executable file gives back:

|

Setting |

Description |

|---|---|

Primary Channel |

Select a channel from the list to define it as the primary channel. In the device tree, PRTG displays the last value of the primary channel below the sensor's name. The available options depend on what channels are available for this sensor.

|

Graph Type |

Define how this sensor shows different channels:

|

Stack Unit |

This setting is only visible if you select Stack channels on top of each other above. Select a unit from the list. PRTG stacks all channels with this unit on top of each other. By default, you cannot exclude single channels from stacking if they use the selected unit. However, there is an advanced procedure to do so.

|

By default, all of these settings are inherited from objects that are higher in the hierarchy. We recommend that you change them centrally in the root group settings if necessary. To change a setting for this object only, click ![]() under the corresponding setting name to disable the inheritance and to display its options.

under the corresponding setting name to disable the inheritance and to display its options.

For more information, see section Inheritance of Settings.

Which channels the sensor actually shows might depend on the target device, the available components, and the sensor setup.

Channel |

Description |

|---|---|

Downtime |

In the channel table on the Overview tab, this channel never shows any values. PRTG uses this channel in graphs and reports to show the amount of time in which the sensor was in the Down status. |

[Value] |

The values that the executable file or script file returns in several channels

|

KNOWLEDGE BASE

What is the Mutex Name in the EXE/Script sensor settings?

How can I test if parameters are correctly transmitted to my script when using an EXE/Script sensor?

How can I show special characters with EXE/Script sensors?

Why do I have to store SQL sensor queries and custom scripts in files on the probe computer?

How can I use meta-scans for custom EXE/Script sensors?

How do I enable and use remote commands in Windows PowerShell?

What security features does PRTG include?