PRTG Manual: SIMATIC S7-300/400 CPU Status Sensor

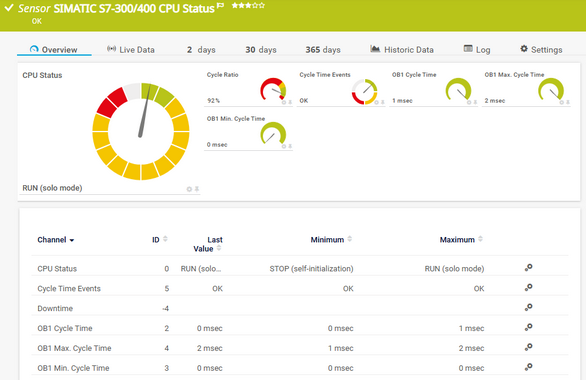

The SIMATIC S7-300/400 CPU Status sensor monitors the CPU status of a Siemens S7-300 or S7-400 Programmable Logic Controller (PLC) via the S7 protocol.

This sensor is in beta status. The operating methods and the available settings are still subject to change. Do not expect that all functions work properly, or that this sensor works as expected at all.

For a detailed list and descriptions of the channels that this sensor can show, see section Channel List.

- Dutch: SIMATIC S7-300/400 CPU Status

- French: SIMATIC S7-300/400 CPU Status

- German: SIMATIC S7-300/400 CPU Status

- Japanese: SIMATIC S7-300/400 CPU Status

- Portuguese: SIMATIC S7-300/400 CPU Status

- Russian: SIMATIC S7-300/400 CPU Status

- Simplified Chinese: SIMATIC S7-300/400 CPU Status

- Spanish: SIMATIC S7-300/400 CPU Status

Consider the following remarks and requirements for this sensor:

Requirement |

Description |

|---|---|

This sensor requires that the Beta Sensors experimental feature is enabled.

|

|

Credentials |

This sensor requires connection settings for Siemens S7 in settings that are higher in the object hierarchy. |

Parent device |

This sensor requires that the parent device is a Siemens S7-300 or S7-400 programmable logic controller. |

IPv4 |

This sensor only supports IPv4. |

Performance impact |

This sensor has a very low performance impact. |

Lookups |

This sensor uses lookups to determine the status values of one or more channels. |

Limits |

This sensor has predefined limits for one or several metrics. |

Scanning interval |

This sensor has a fixed minimum scanning interval for performance reasons. You cannot use a shorter scanning interval. Consequently, shorter scanning intervals in the Monitoring settings are not available for this sensor.

|

The sensor has the following default tags that are automatically predefined in the sensor's settings when you add the sensor:

- plc

- s7

- s7cpustatussensor

- siemens

For more information about basic sensor settings, see section Sensor Settings.

Setting |

Description |

|---|---|

Define a maximum cycle time for the program cycle organization block (OB1) in milliseconds. PRTG uses this value to calculate the value of the Cycle Ratio channel. Enter a positive integer.

|

Setting |

Description |

|---|---|

Primary Channel |

Select a channel from the list to define it as the primary channel. In the device tree, PRTG displays the last value of the primary channel below the sensor's name. The available options depend on what channels are available for this sensor.

|

Graph Type |

Define how this sensor shows different channels:

|

Stack Unit |

This setting is only visible if you select Stack channels on top of each other above. Select a unit from the list. PRTG stacks all channels with this unit on top of each other. By default, you cannot exclude single channels from stacking if they use the selected unit. However, there is an advanced procedure to do so. |

Setting |

Description |

|---|---|

Result Handling |

Define what PRTG does with the sensor result:

|

By default, all of these settings are inherited from objects that are higher in the hierarchy. We recommend that you change them centrally in the root group settings if necessary. To change a setting for this object only, click ![]() under the corresponding setting name to disable the inheritance and to display its options.

under the corresponding setting name to disable the inheritance and to display its options.

For more information, see section Inheritance of Settings.

Which channels the sensor actually shows might depend on the target device, the available components, and the sensor setup.

Channel |

Description |

|---|---|

CPU Status |

The CPU status of the PLC

|

Cycle Ratio |

This channel is only visible if you define a maximum OB1 cycle time during sensor creation. The cycle ratio of the PLC. PRTG divides the most recent OB1 cycle time by the maximum cycle time you define in the Maximum OB1 Cycle Time to calculate this value.

|

Cycle Time Events |

If the Cycle Time Exceeded (W#16#3501) event occurred

|

Downtime |

In the channel table on the Overview tab, this channel never shows any values. PRTG uses this channel in graphs and reports to show the amount of time in which the sensor was in the Down status. |

OB1 Cycle Time |

The most recent OB1 cycle time |

OB1 Max. Cycle Time |

The maximum OB1 cycle time since the last restart of the PLC |

OB1 Min. Cycle Time |

The minimum OB1 cycle time since the last restart of the PLC |

KNOWLEDGE BASE

What are beta sensors and how can I use them?

What security features does PRTG include?