Custom alerts and data visualization let you quickly identify and prevent OT network performance issues.

Modbus, initially used in industrial manufacturing, is now in almost every sector, including cloud services, e-health, security, telecommunications, and even farming, among others. Whether your IT systems use Modbus RTU or Modbus TCP-enabled devices, having a 24/7/365 watchdog on your Modbus network is critical to business continuity. Paessler PRTG Modbus monitoring is your solution to keep Modbus data transfer and your Modbus communications going strong.

Diagnose network issues by continuously tracking your Modbus RTUs and other devices. Show system performance, statistics, troubleshooting information, and other custom metrics in real time. Visualize monitoring data in clear graphs and dashboards to identify problems more easily. Gain the overview you need to troubleshoot Modbus communications and other issues in your OT network.

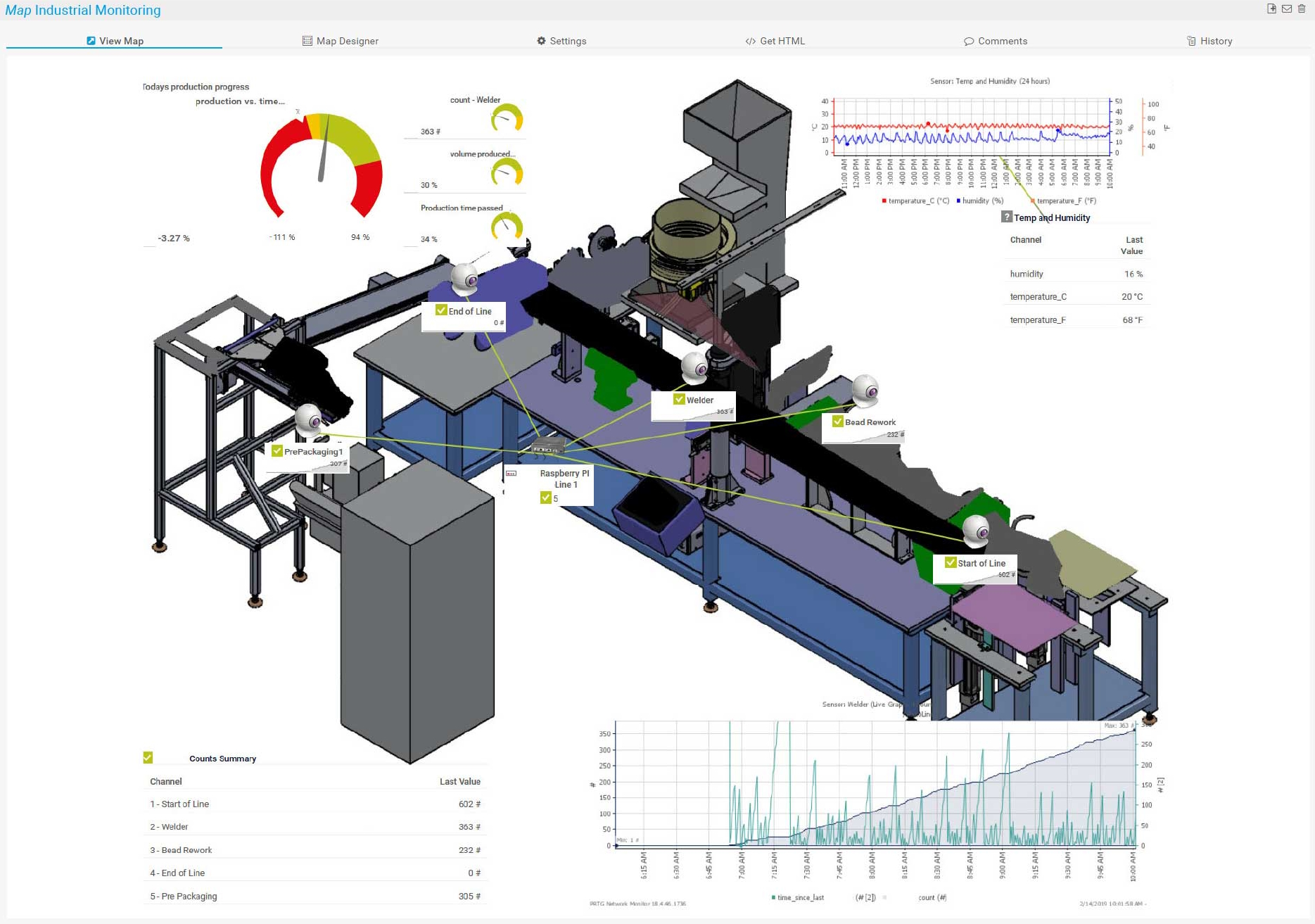

Industrial monitoring overview

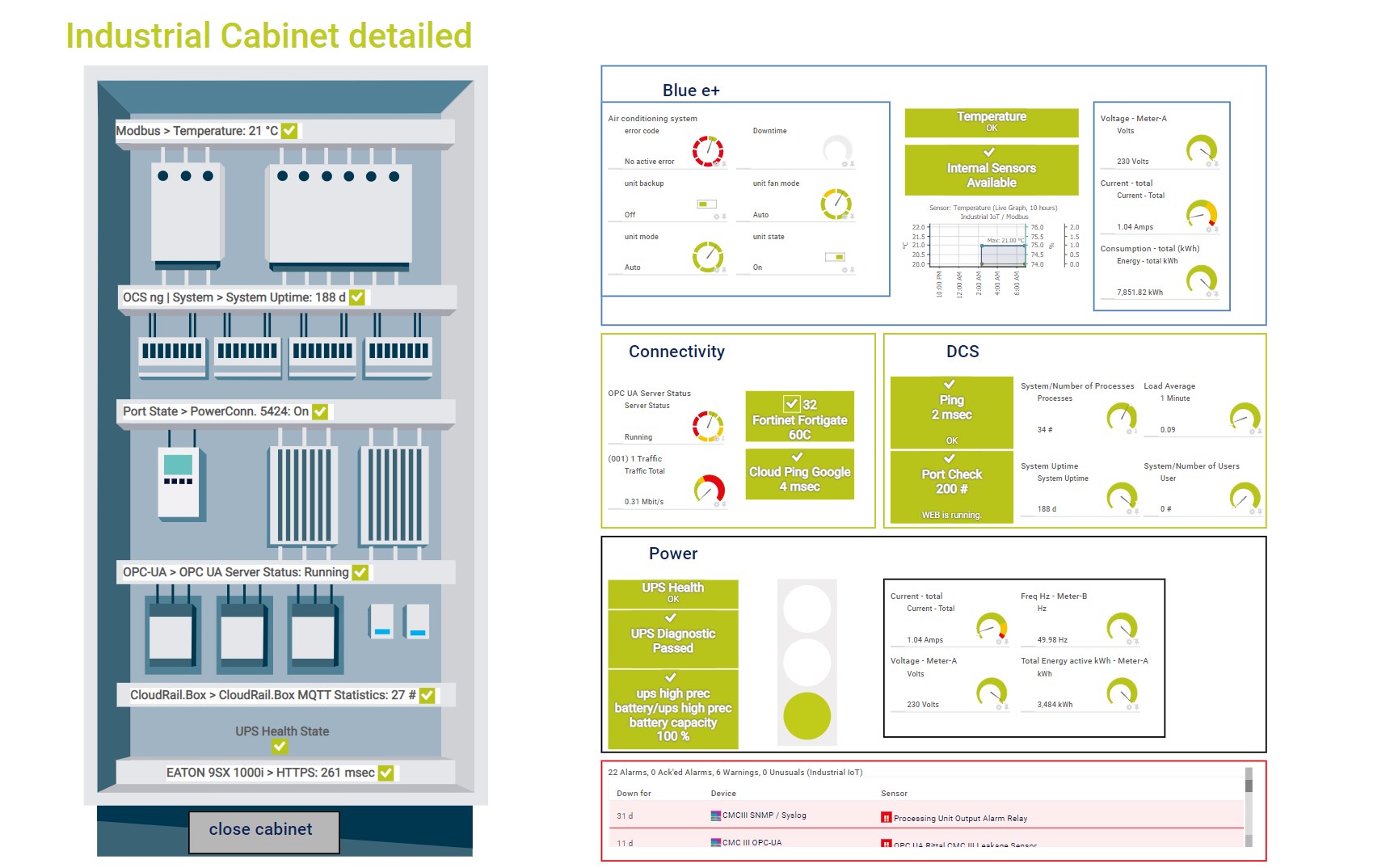

Open industrial cabinet map

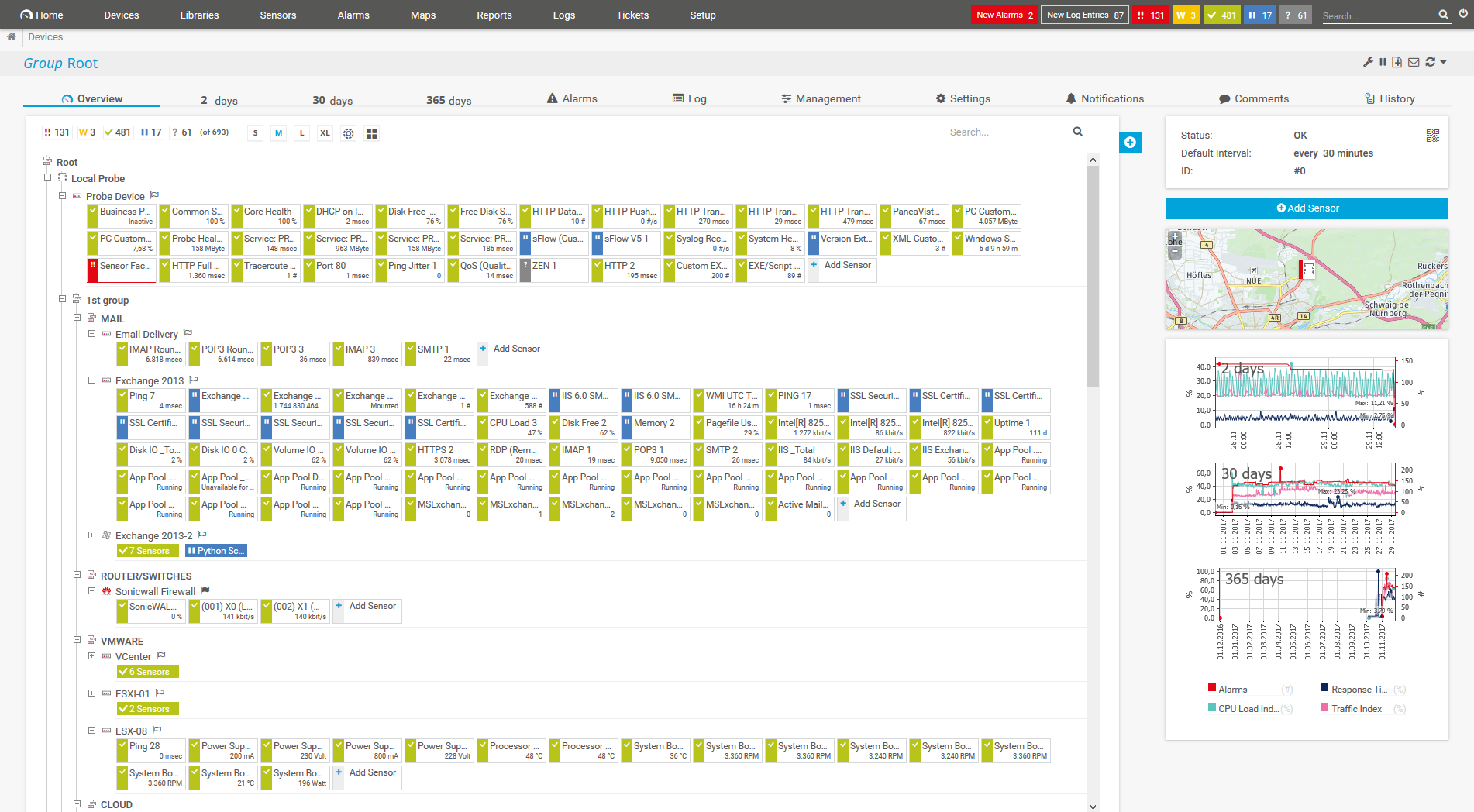

Device tree view of the complete monitoring setup

Custom PRTG dashboard for keeping an eye on the entire IT infrastructure

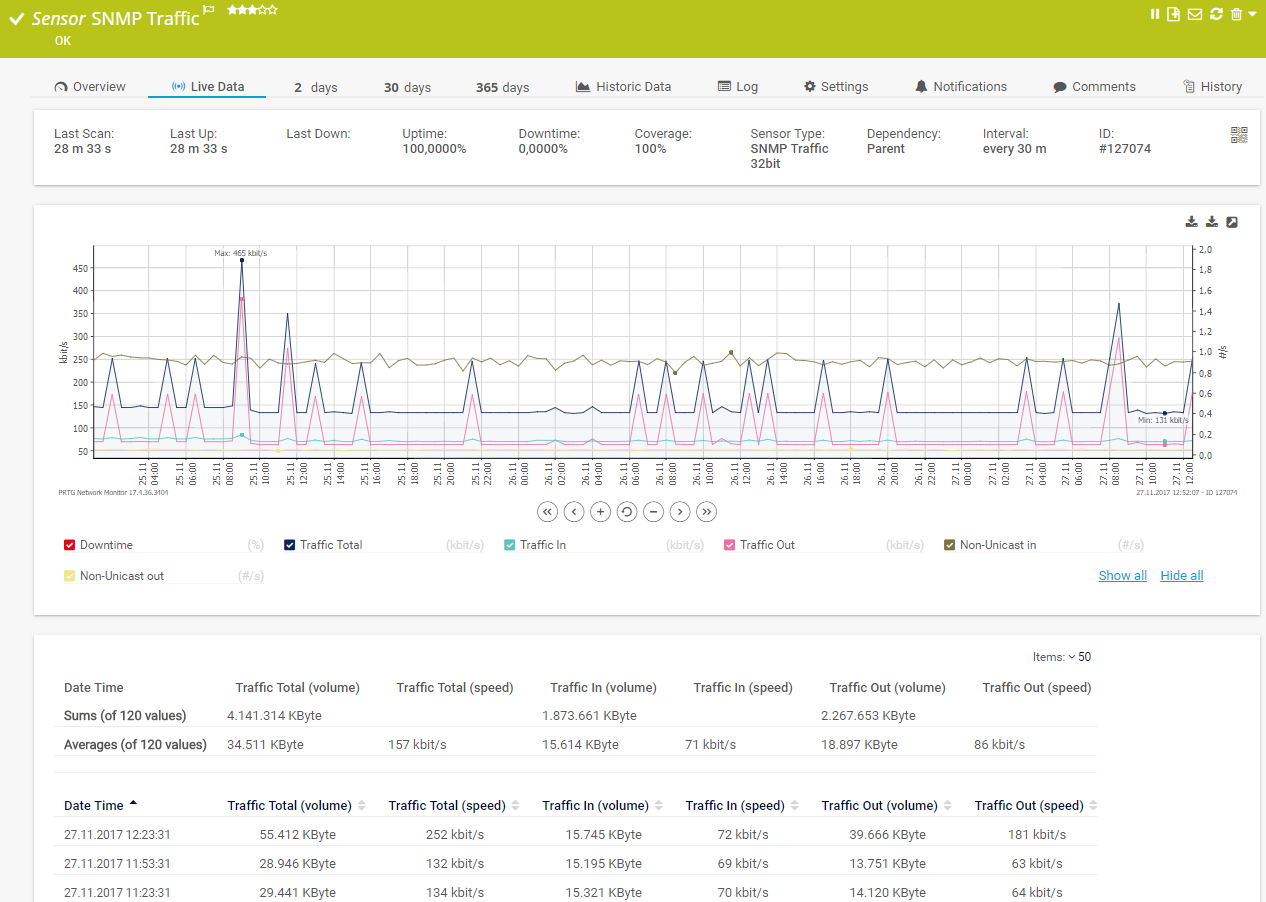

Live traffic data graph in PRTG

PRTG comes with more than 250 native sensor types for monitoring your entire on-premises, cloud, and hybrid cloud environment out of the box. Check out some examples below!

See the PRTG Manual for a list of all available sensor types.

Real-time notifications mean faster troubleshooting so that you can act before more serious issues occur.

Set up PRTG in minutes and use it on almost any mobile device.

“Excellent tool for detailed monitoring. Alarms and notifications work greatly. Equipment addition is straight forward and server initial setup is very easy. ...feel safe to purchase it if you intend to monitor a large networking landscape.”

Partnering with innovative IT vendors, Paessler unleashes synergies to create

new and additional benefits for joined customers.

IT that works constitutes a business-critical basis for a company's success. Availability and security must be defined for the respective purpose and closely monitored – by OT and IT alike.

Integrating monitoring results from PRTG into NetBrain maps makes the foundation for network automation.

With ScriptRunner Paessler integrates a powerful event automation platform into PRTG Network Monitor.

Custom alerts and data visualization let you quickly identify and prevent OT network performance issues.

Network Monitoring Software – Version 25.3.110.1313 (August 27, 2025)

Download for Windows and cloud-based version PRTG Hosted Monitor available

English, German, Spanish, French, Portuguese, Dutch, Russian, Japanese, and Simplified Chinese

Network devices, bandwidth, servers, applications, virtual environments, remote systems, IoT, and more

Choose the PRTG Network Monitor subscription that's best for you

Modbus is a data communications server-client protocol originally for use with programmable logic controllers (PLC). It’s become a standard communications protocol, commonly available to connect industrial electronic devices. Free and openly published, Modbus is popular in industrial environments and many other industries. PRTG offers two native Modbus sensors, the Modbus TCP Custom and the Modbus RTU Custom sensor.

Communication modes

Modbus operates in two primary modes:

Master-slave architecture

In a typical setup, one master can communicate with multiple slaves, each identified by a unique address.

Data frames and communication

Modbus communication is based on a request-response model, where the master sends a request frame, and the slave responds with a response frame. The frame structure is different for Modbus RTU and Modbus TCP/IP, but the core principles are similar.

Modbus monitoring keeps a continual watch on your Modbus network. It provides real-time data analysis, allowing more informed decision-making. By integrating Modbus RTU and Modbus TCP into PRTG and monitoring it, you can get information about the status of PLCs, HVAC systems, detailed information from energy metering systems, and much more.

Both are Modbus protocols, but they have different uses. Modbus TCP is suitable for modern Ethernet-based industrial networks and is designed for TCP/IP network communication. Modbus RTU, on the other hand, uses RS-232 or RS-485 serial communication and is more common in legacy systems or limited network structures.

No. PRTG Modbus sensors have a very low-performance impact.

In PRTG, “sensors” are the basic monitoring elements. One sensor usually monitors one measured value in your network, for example the traffic of a switch port, the CPU load of a server, or the free space on a disk drive. On average, you need about 5-10 sensors per device or one sensor per switch port.

Paessler conducted trials in over 600 IT departments worldwide to tune its network monitoring software closer to the needs of sysadmins. The result of the survey: over 95% of the participants would recommend PRTG – or already have.

Paessler PRTG is used by companies of all sizes. Sysadmins love PRTG because it makes their job a whole lot easier.

Bandwidth, servers, virtual environments, websites, VoIP services – PRTG keeps an eye on your entire network.

Everyone has different monitoring needs. That’s why we let you try PRTG for free.