Converged industrial

IT & OT monitoring in

a single tool

- Unified overview of your entire IT, OT, and IIoT infrastructure in a single pane of glass

- Health and condition monitoring of components like PLCs, IPCs, or control systems

- Monitoring of industrial devices of the most important manufacturers

5 reasons why experts monitor industrial IT with PRTG

IT/OT convergence, Industry 4.0, and increased digitalization all shape the way the production floor connects and interacts with IT. This interconnectivity makes it crucial to have a central overview

of your entire infrastructure.

- Get out-of-the-box support for common industrial standards & protocols (OPC UA, MQTT, Modbus, and more)

- Collect data about the factory floor and IIoT from industrial gateways

- Keep an eye on industrial ethernet devices in your OT environment

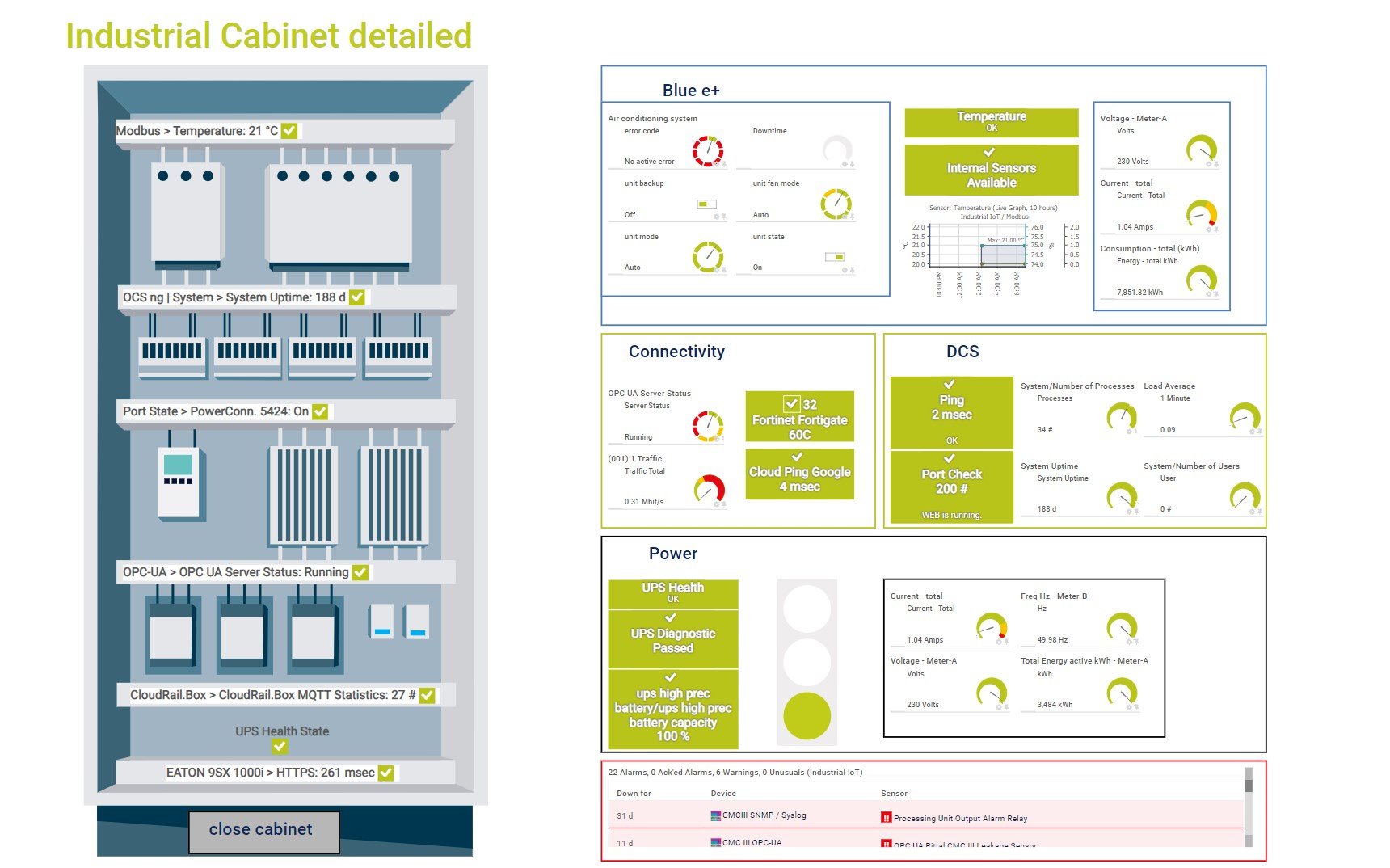

- Visualize your environment in dashboards that bring together IT, OT, and IIoT elements

- Extend the functionality of common industry solutions with comprehensive monitoring

IT/OT convergence makes industrial IT monitoring with a single solution essential

Traditionally, classic IT networks were monitored separately from OT components, if the OT was monitored at all. Because of the increased digitalization and connectivity of OT environments, however, keeping an eye on both IT and OT becomes more and more important. So why should you monitor industrial IT?

Get the right data to the right teams

Previously segregated teams now rely on each other. For example: IT teams are responsible for ensuring that the data generated by machines on the factory floor makes its way to the cloud, while industrial engineers or managers might need access to that data to make decisions regarding the production line or to implement predictive maintenance strategies. All teams need to work from the same data, but they need different views of it.

Prevent issues with root cause analysis

Because data flows through several systems, all gears need to work flawlessly together: if one doesn’t work, other processes will be impacted, too. If a failure occurs, a simple alert to troubleshoot the issue is not enough. Teams need to understand the root cause of a problem to prevent it from happening in the future. But to find the root cause, teams need to look across systems and interfaces.

Keep data flowing without interruption

Digitalization has made it vital to be able to generate and analyze insights using data from all parts of the enterprise. Data created on the factory floor must be aggregated and sent to upstream on-premises or cloud systems for processing. Because this data travels across OT and IT networks, it’s essential to monitor that it flows correctly through various interfaces and touchpoints in the infrastructure.

Discover our new product extension

Paessler PRTG OPC UA Server

Get an overview of OT network components in your supervisory and control systems

Do you want to have a full overview of your OT environment in your supervisory and control systems – including traditional IT network components like routers, switches, firewalls, and more?

PRTG OPC UA Server consolidates monitoring data from your OT network and the IIoT in your control system. View all your data in one place for centralized monitoring and alarms.

Start monitoring the health, status and condition of machines, control systems, devices, and more across your IT and OT networks with our industrial IT monitoring solution PRTG.

Why PRTG is the industrial IT monitoring tool of your choice

Minimize failures and downtime

- Receive real-time alerts if there is an issue, for example, if a machine is down

- Prevent downtimes with condition monitoring & preventative maintenance

- Analyze historical data to identify patterns & trends for future planning

Control the consumption of energy

- Know how much energy machines and devices are using in the long run

- Collect energy usage data from IoT sensors or from supervisory & control systems

- Identify areas where you can reduce energy consumption most efficiently

Collect data from various sources

- Benefit from support for IT protocols & industry standards and protocols alike

- Collect data directly from IIoT hardware sensors on the production lines

- Integrate industrial gateways like INSYS icom to get access to shop floor data

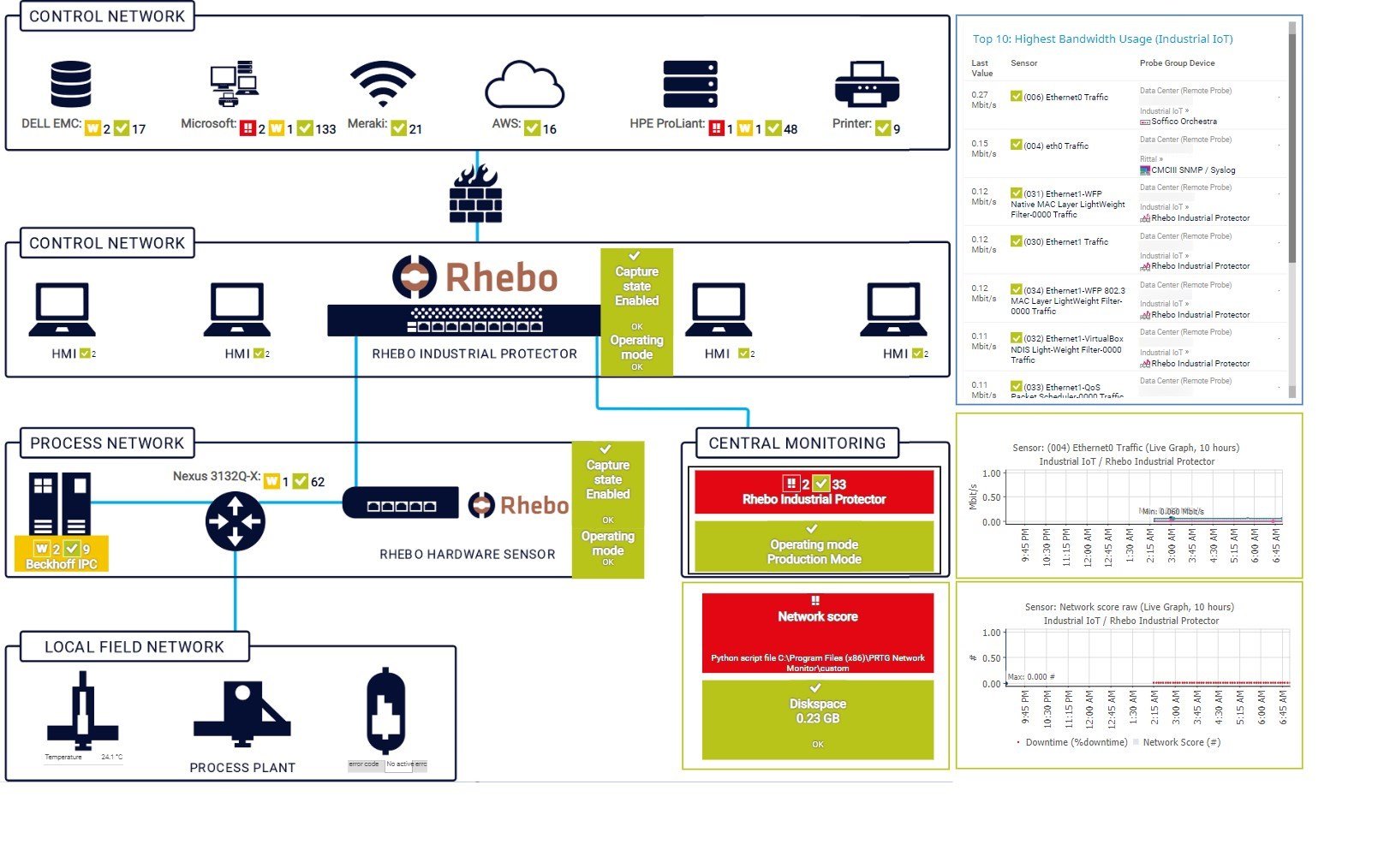

Make the network more secure

- Use PRTG alongside common cyber security tools & intrusion detection systems

- Continuously check for potential breaches or suspicious and unusual activity

- Keep track of what is generating traffic in the network round the clock

Ensure the continuous flow of data

- Ensure that the data required for analysis or processing moves without interruptions

- Monitor the continuous flow of data at critical interfaces & touchpoints in the infrastructure

- Watch data collection (factory floor), processing (gateway), and analysis (upstream target)

Extend 3rd-party tool functions

- Extend capabilities of passive monitoring tools like Rhebo with active monitoring

- Maximize cyber security monitoring and analysis by integrating PRTG and Moxa

- Integrate PRTG with tools for monitoring retrofitted machines, like Schildknecht

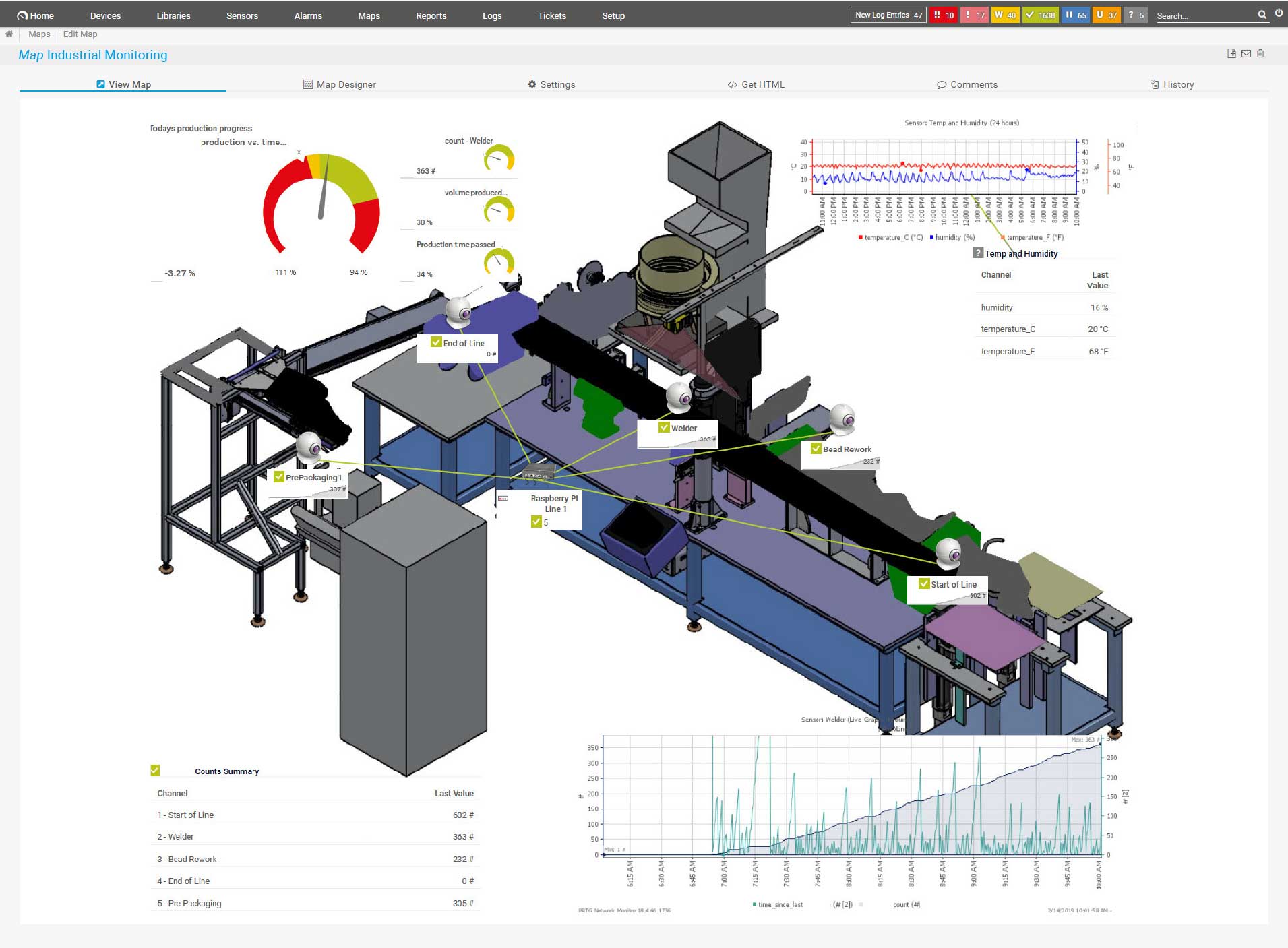

What IT/OT monitoring looks like in PRTG

Diagnose issues with your industrial IT infrastructure by continuously monitoring your industrial devices, edge computing environment, IT hardware, applications, and more. Show monitoring data in real time and visualize it in graphic maps & dashboards to identify problems more easily. Gain the visibility you need to troubleshoot issues before they become critical.

“Great interface, intuitive, full REST support. custom scripts, rest sensors add extra value. We have been using PRTG for 10 years now in multiple environments and use cases. it has by far the best interface and very easy to setup without prior experience.”

Dev Ops Manager, Industry: Manufacturing, Role: R&D/Product Development, Firm Size: 500M-1B USD

Start monitoring the health, status and condition of machines, control systems, devices, and more across your IT and OT networks with our industrial IT monitoring solution PRTG.

Industrial IT monitoring brochure:

Get to know PRTG in the industrial environment

In modern, digitalized industrial environments, the worlds of IT and OT are interconnected. This includes programmable logic controllers, industrial PCs, smart industrial gateways, and IoT sensor technology, as well as traditional IT infrastructure components like network switches, routers, and wireless components.

Read our brochure about industrial IT monitoring with PRTG and find out how you can bring your IT and OT environments together in a single view.

The PRTG advantage: Preconfigured sensors for monitoring your industrial environment

Beyond out-of-the-box integrations for all classic IT standards, PRTG offers a REST API as well as

JSON, OPC UA, Modbus, and MQTT support. Easily integrate OT components, IoT hardware sensors, as well as IT devices and applications with our preconfigured PRTG sensors.

MQTT sensors

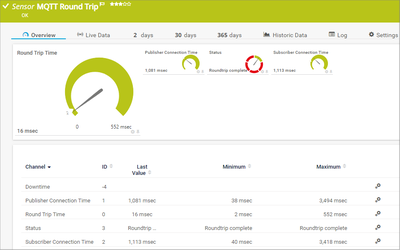

MQTT Round Trip

The sensor MQTT Round Trip monitors the availability of an MQTT broker (server). The sensor connects to the broker as a publishing and subscribing client and sends the data packets using a predefined topic. It can show the following parameters:

- Publisher connection time

- Round trip time

- Round trip status

- Subscription connection time

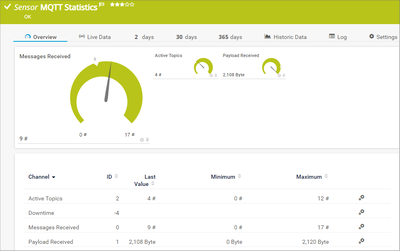

MQTT Statistics

The sensor MQTT Statistics monitors an MQTT topic. The sensor can show the following parameters:

- Active topics

- Number of received messages

- Received payload

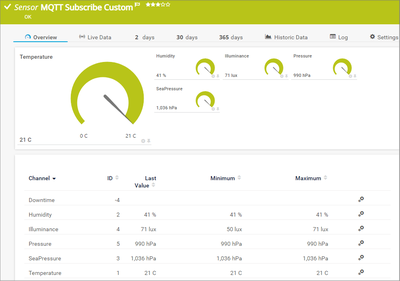

MQTT Subscribe Custom

The sensor MQTT Subscribe Custom monitors numeric values returned by an MQTT topic that the sensor subscribed to. The sensor can show, for example, environmental parameters like temperature, humidity, illuminance, or pressure.

Modbus sensors

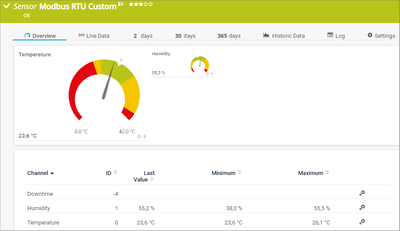

Modbus RTU Custom

The sensor Modbus RTU Custom monitors custom numeric values returned by a Modbus Remote Terminal Unit (RTU). The sensor can show, for example, temperature and humidity.

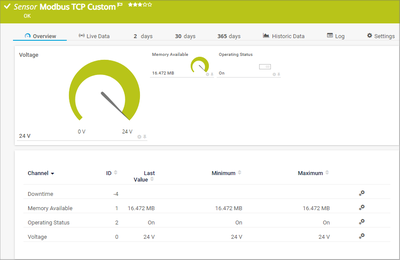

Modbus TCP Custom

The sensor Modbus TCP Custom monitors custom numeric values returned by a Modbus Transmission Control Protocol (TCP) server. The sensor can show, for example, the available memory, voltage, and operating status.

OPC UA sensors

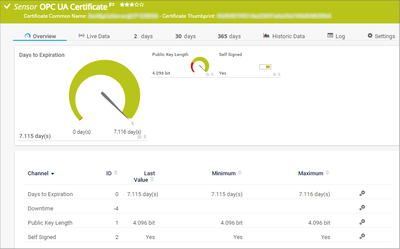

OPC UA Certificate

The sensor OPC UA Certificate monitors the certificate of an OPC UA server. The sensor can show the following parameters:

- Days to expiration

- Public key length

- Self-signed certificate

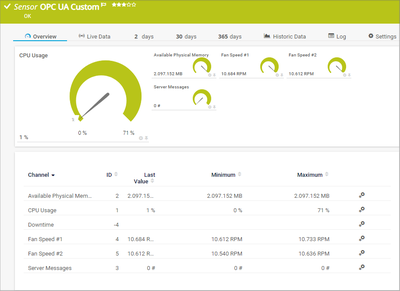

OPC UA Custom

The sensor OPC UA Custom monitors custom numeric values returned by specific OPC UA node IDs. The sensor can show, for example:

- CPU usage

- Available physical memory

- Fan speed

- Number of server messages

OPC UA Server Status

The sensor OPC UA Server Status monitors the health status of an OPC UA server. The sensor can show the following parameters:

- Number of rejected requests and sessions

- Number of security-rejected requests and sessions

- Server status

- Number of sessions, session aborts, and session timeouts

- Number of subscriptions

- Uptime

Rittal sensor

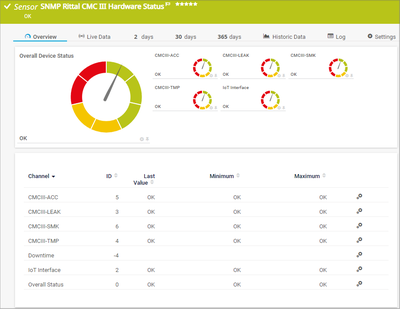

SNMP Rittal CMC III Hardware Status

The sensor SNMP Rittal CMC III Hardware Status monitors the overall status of Rittal data center hardware, for example Rittal Computer Multi Control version 3 (CMC III) processing units, Rittal power distribution units (PDU), or Rittal IoT Interfaces and the hardware status of every attached external sensor.

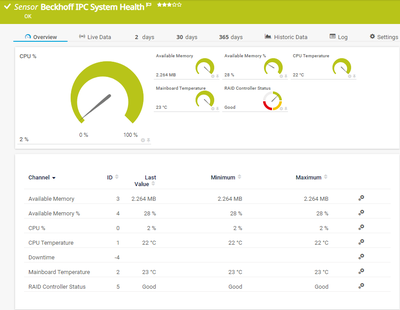

Beckhoff sensor

Beckhoff IPC System Health

The sensor Beckhoff IPC System Health monitors the system health of Beckhoff industrial PCs. The sensor can show the following parameters:

- Available memory

- CPU load and temperature

- Mainboard temperature

- RAID controller status

Get your free white papers

White paper I

In modern industrial IT, the right teams need the right data. Our guide shows how to implement holistic monitoring that brings elements from IT, OT and IIoT into your dashboards.

White paper II

Our second guide gives you inspiration and ideas for dashboards that feature IT, OT and IIoT data – all in one place. We show you what truly convergent industrial dashboards look like!

Start monitoring the health, status and condition of machines, control systems, devices, and more across your IT and OT networks with our industrial IT monitoring solution PRTG.

Success stories from our customers

Companies around the world trust PRTG Network Monitor when it comes to ensuring that their IT systems run smoothly.

F.T.P. relies on Paessler PRTG for high-performance monitoring

FTP has 20 years of experience providing IT consulting to the most established automotive companies in Italy’s Motor Valley. System integration, cyber security, managed services, and industrial technology are their main areas of expertise. From a strong focus on the enterprise environment to the world of SMEs: F.T.P. offers high-value monitoring services through PRTG and enters new markets, including OT.

Paessler PRTG helps SMS group to digitize the production of steel

SMS group GmbH provides production plants for the steel industry worldwide that rely on modern control technology as well as automation systems with corresponding real-time networks. The company uses PRTG to ensure performance and reliability during the construction, testing, and start-up of metallurgical plants (steel production plants), and thereby optimizes the quality of its production lines.

Paessler PRTG is perfectly suited for monitoring the Industrial Automation DataCenter from Siemens

Siemens AG is a German corporation that focuses on industrial automation and digitalization, building infrastructure, distributed energy systems, rail and road mobility, and medical technology. Its Industrial Automation DataCenter (IADC) is an individually configured data center for on-site use in manufacturing. PRTG monitors all components of the IADC, providing a comprehensive overview.

CANCOM GmbH

connecT SYSTEMHAUS

We are your reliable and qualified partner for all issues related to digitalization.

Marktstraße 45a

57078 Siegen

Germany

+49 271 488 73 - 73

Dätwyler IT Infra AG

Your worldwide partner for IT and OT system integration and monitoring

Gotthardstrasse 31

6460 Altdorf, Switzerland

+41 41 875 32 33

F.T.P. S.r.l.

We support our clients in their journey to integrate and interconnect the IT network with the OT one.

Via Grazia Deledda, 38

41043 Formigine MO, Italy

+39 059 5961 333

GIA

Your partner for process automation and

IT services.

Dönhoffstr. 39

51373 Leverkusen

Germany

+49 214 83067-0

ikt Gromnitza

Customized solutions to generate the perfect fit between your processes and software landscape.

Kirchener Str. 12

57518 Betzdorf

Germany

+49 2741 18222-0

Hirschmann Network Solutions

Your partner for IP-based (W)LAN solutions in industrial and infrastructural environments.

Pampuslaan 170

1382 JS Weesp, Netherlands

+31 294 46 25 67

Kessler

One team-one strategy: Automation technology, IT/OT concepts, virtualization & engineering of complex process control systems and cyber-security 24/7

Kessler Process Automation

10, rue Martin Maas (Z.I.)

6468 Echternach, Luxemburg

+352 267234-1

www.kessler-pa.lu

Kriko Engineering

Recording, reporting and analysis of process data. KRIKO is your partner in the matter of process automation and in the development of customer-specific interfaces.

Zum Engelberg 20

79249 Merzhausen, Germany

+49(0)761/40078-0

Kutzschbach

Modern IT-concepts and cloud solutions for your business, automation technology and industrial monitoring.

Markham Str. 15

86720 Nördlingen, Germany

+49 9081 2503400

Metrix

Metrix uses sensing, monitoring and analytics to create business value within Industry 4.0, logistics, building maintenance and healthcare.

Calle Santander, 11, Piso 1, oficina 2

09004 Burgos

Spain

+34 610 099 578

M³H²

Solutions for the synchronized recording of mixed signals like EtherCat, CAN, High Speed cameras, analog and digital signals.

Rambertweg 9

80995 Munich

Germany

+49 89 1894959-0

netmon24

As a long-term partner, netmon24 offers you customized solutions within IT, digitalization as well as IoT.

Dietkircher Str. 3

65552 Limburg an der Lahn, Germany

+49 6431 598700

PCI Industrial Automation

Consultation services in industrial automation and system integration.

9500 Meilleur St., Suite 601

Montreal, QC, H2N 2B7, Canada

514-336-0388

PLT networks GmbH

We deliver cross-manufacturer solutions for IT and OT environments that benefit from our global experience in industrial automation.

Robert-Schuman-Platz 2

54634 Bitburg, Germany +49 6561 / 948330

Process Automation Solutions

Process Automation Solutions serves customers in automotive, chemical, pharmaceutical / biotech, food & beverage, oil & gas and other industries.

More than 50 branch offices in Europe, America and Asia

SIGMA Process & Automation

Your partner for automating processes and Plant-Intelligence/MES.

Erlengrund 9

63773 Goldbach

Germany

+49 6021 4392220

Vescon Aqua GmbH

We are a leading international industrial services provider.

Heidenkampsweg 101

20097 Hamburg

Germany

+49 40 23 64 854 - 0

WDL Systems

WDL Systems is a leading source for AI, Industrial IoT and Edge Computing.

220 Chatham Business Drive

Pittsboro, NC 27312, United States

800-548-2319

xinfra

Your partner for IT and IoT monitoring services.

Wildischachenstrasse 36

5200 Brugg, Switzerland

+41 56 544 2222

Industrial IT monitoring: FAQ

1. What is industrial IT?

Industrial IT refers to the application of modern information and communication technologies in industrial processes and manufacturing environments. It involves the integration of various IT systems, software, and hardware components to optimize and automate industrial operations, enhance productivity, increase efficiency, and improve overall business performance.

The goal of industrial IT is to create a more interconnected, data-driven, and efficient industrial environment. It can be applied across various industries, including manufacturing, energy, transportation, healthcare, agriculture, and more.

The integration of technology into industrial processes can lead to cost savings, improved product quality, increased safety, reduced downtime, and better utilization of resources.

2. What is the role of monitoring industrial IT?

Industrial IT monitoring plays a crucial role in maintaining and optimizing the performance of industrial processes, systems, and equipment. It involves the continuous collection, analysis, and visualization of data from various sources within an industrial environment.

The primary purpose of industrial IT monitoring is to ensure that operations are running smoothly, identify potential issues or anomalies, and enable timely intervention to prevent disruptions.

Industrial IT monitoring is also a proactive approach to managing industrial processes and equipment. It enables companies to enhance efficiency, reduce downtime, increase product quality, and maintain a competitive edge by leveraging real-time data and insights for continuous improvement.

3. What benefits does the convergence of IT and OT provide for the manufacturing sector?

IT/OT convergence, referring to the integration of Information Technology (IT) and Operational Technology (OT) systems, offers several compelling benefits for organizations in various industries. Here are some reasons why you should consider IT/OT convergence:

- Improved visibility and decision-making: Converging IT and OT systems provides a unified view of both business operations and industrial processes. This comprehensive visibility allows for better-informed decision-making, as you can understand how IT data (like business metrics) and OT data (like production metrics) interact and impact each other.

- Efficient data utilization: IT systems are adept at handling and analyzing large volumes of data, while OT systems generate vast amounts of operational data. Convergence enables the efficient utilization of data from both domains, leading to insights that were previously hidden when the systems were separate.

- Enhanced efficiency and productivity: When IT and OT systems are integrated, processes can be streamlined and automated more effectively. This leads to increased operational efficiency, reduced manual intervention, and ultimately higher productivity.

- Predictive maintenance: Converged systems enable the implementation of predictive maintenance strategies. By analyzing data from IT and OT sources, you can predict equipment failures and schedule maintenance activities before issues cause downtime or disruptions.

- Cost savings: By optimizing operations through data-driven decisions, reducing downtime, and minimizing equipment failures, IT/OT convergence can lead to significant cost savings in terms of maintenance, energy consumption, and resource utilization.

- Security improvements: While convergence increases connectivity, it also highlights the importance of robust cybersecurity measures. By addressing security concerns across both IT and OT domains, you can enhance overall system resilience and reduce vulnerabilities.

- Adaptation to industry trends: Modern industries are becoming more digitalized and interconnected. IT/OT convergence positions your organization to adapt to these industry trends effectively and remain competitive.

4. How can an industrial IT monitoring tool help me?

An industrial IT monitoring tool like Paessler PRTG can provide you with a range of benefits:

- Real-time visibility: An industrial IT monitoring tool allows you to monitor your industrial processes and equipment in real time. You can visualize critical data such as temperatures, pressures, flow rates, and other process variables, giving you an instant overview of your operations.

- Anomaly detection: The monitoring tool can automatically detect anomalies or deviations from normal operating conditions. This early detection helps you identify potential issues before they escalate into larger problems, allowing for timely intervention and maintenance.

- Data analytics: Industrial IT monitoring tools often include analytics capabilities that allow you to perform in-depth analysis of your data. You can identify patterns, correlations, and trends that can guide decision-making for process improvements and operational strategies.

- Remote monitoring: Many monitoring tools offer remote access, enabling you to monitor your operations from anywhere. This is particularly useful for overseeing multiple sites or when you need to make quick decisions while off-site.

- Alerts and notifications: The tool can send alerts and notifications when predefined thresholds are exceeded or anomalies are detected. This ensures that you're promptly informed about critical situations that require attention.

- Regulatory compliance: For industries with regulatory requirements, monitoring tools can help you collect and document the necessary data to meet compliance standards. This simplifies reporting and auditing processes.

- Data visualization: Monitoring tools often include customizable dashboards and visualizations that allow you to present data in a clear and understandable format. Visualizations make it easier to track key performance indicators and make informed decisions.

- Improved decision-making: Access to real-time and historical data empowers you to make informed decisions based on accurate information. This can lead to better strategic planning and operational execution.

- Integration with other systems: Many monitoring tools can integrate with other software systems, such as ERP (Enterprise Resource Planning) or CMMS (Computerized Maintenance Management System), creating a unified ecosystem that enhances overall operational efficiency.

5. What is a sensor in PRTG?

In PRTG, “sensors” are the basic monitoring elements. One sensor usually monitors one measured value in your network, for example the traffic of a switch port, the CPU load of a server, or the free space on a disk drive.

On average, you need about 5-10 sensors per device or one sensor per switch port.

Get more deep-dive information about industrial IT monitoring

Monitoring a production line with PRTG

Read about how a biological scientist with an IT background and an IT network administrator built an inexpensive yet powerful production monitoring system with PRTG and simple sensors connected to a Raspberry PI.

Free webinar: PRTG keeps an eye on your industrial IT

Watch this free webinar to get an overview of our PRTG sensors for industrial IT (MQTT, Modbus, OPC UA, and more). In addition, we’ll show you use cases to demonstrate how these sensors can help you master your daily challenges in IT and OT monitoring.

Resources for industrial IT monitoring at a glance

For more insights into and information about PRTG in the industrial sector, have a look at our industrial resource center page. Find out about use cases, industrial IT knowledge, industrial alliances, and Paessler-recommended industrial IT partners.

Your leading partner for the digital transformation of your IT and OT infrastructure.

Erika-Mann-Str. 69

80636 Munich

Germany