Swiss precision digitalization thanks to Paessler PRTG

About Dätwyler IT Infra

With roots dating back more than 100 years as a manufacturer of electrical conductors, Dätwyler IT Infra has evolved into a global provider of comprehensive IT and OT infrastructure solutions. The company supports its customers through digitalization initiatives by combining traditional Swiss values like quality and reliability with international expertise. Their portfolio of proprietary products serves as the foundation for projects across data centers, smart factories, and intelligent buildings—ranging from cutting-edge cable technology and WLAN networks to complete data center systems.

Video: From reactive to proactive – How Dätwyler prevents downtime with PRTG

Dätwyler’s services extend well beyond implementation, encompassing the entire value chain. As a Paessler PRTG reseller, they deliver additional benefits to end customers. Beyond products and services, Dätwyler offers comprehensive consulting on monitoring strategy and IT system architecture. They handle knowledge transfer, server updates, and provide critical incident alerts for end customers.

Continuous and comprehensive monitoring of customer networks, infrastructures, and digital environments is essential to their approach. Dätwyler has adopted Paessler PRTG as their cross-divisional monitoring solution. Pascal Walther, Head of IT/OT at Dätwyler IT Infra, explains:

“Monitoring IT, edge and OT with a holistic solution is the prerequisite for successful digitalization. With Paessler PRTG, we have the ideal tool for this: lean and efficient, comprehensive and easy to use. With our expertise, we can offer customers an external monitoring service based on PRTG that is independent and secure on the one hand and includes everything on the other—from the OT environment and edge devices to the IT infrastructure and network.”

“Monitoring IT, edge and OT with a holistic solution is the prerequisite for successful digitalization. With Paessler PRTG, we have the ideal tool for this: lean and efficient, comprehensive and easy to use. With our expertise, we can offer customers an external monitoring service based on PRTG that is independent and secure on the one hand and includes everything on the other—from the OT environment and edge devices to the IT infrastructure and network.”

Pascal Walther, Head of IT/OT at Dätwyler IT Infra

The foundation: The data center

The data center forms the foundation of digitalization, housing the servers and network core. Comprehensive monitoring is essential for both the server infrastructure and the data center infrastructure—including PDUs, temperature monitoring systems, and sensors.

After a brief evaluation period, Dätwyler selected Paessler PRTG as their monitoring solution. This decision was influenced by their prior familiarity with PRTG, while the open-source alternative Nagios was quickly eliminated due to its high complexity and the substantial resources required for implementation and maintenance.

As a comprehensive IT monitoring platform, PRTG provides out-of-the-box support for virtually all IT components in use. The monitoring of IT components primarily utilizes SNMP sensors along with WMI and PowerShell sensors.

Digitalization in production

Industrial plants should ideally be planned and built entirely digitally from the ground up. However, this remains more exception than rule. Consequently, existing plants and machinery typically require modernization and integration into contemporary environments. At Dätwyler, the catalyst for digitalization was their diverse machine park and the need for Industry 4.0 solutions to better leverage existing data for efficiency and predictive maintenance purposes.

For instance, at Dätwyler’s own facilities, temperature is monitored throughout the cable sheathing process. A dedicated digitalization team at Dätwyler focuses on implementing such projects. This work is particularly important because production systems are generally designed with much longer lifecycles than IT components. These circumstances necessitate brownfield transformation and retrofitting approaches.

The result is typically highly heterogeneous industrial environments where modern, fully digitized systems operate alongside older machines that must be integrated through new digital control systems. Consequently, quality control systems must be capable of recording and monitoring both cutting-edge digital technology and retrofitted systems.

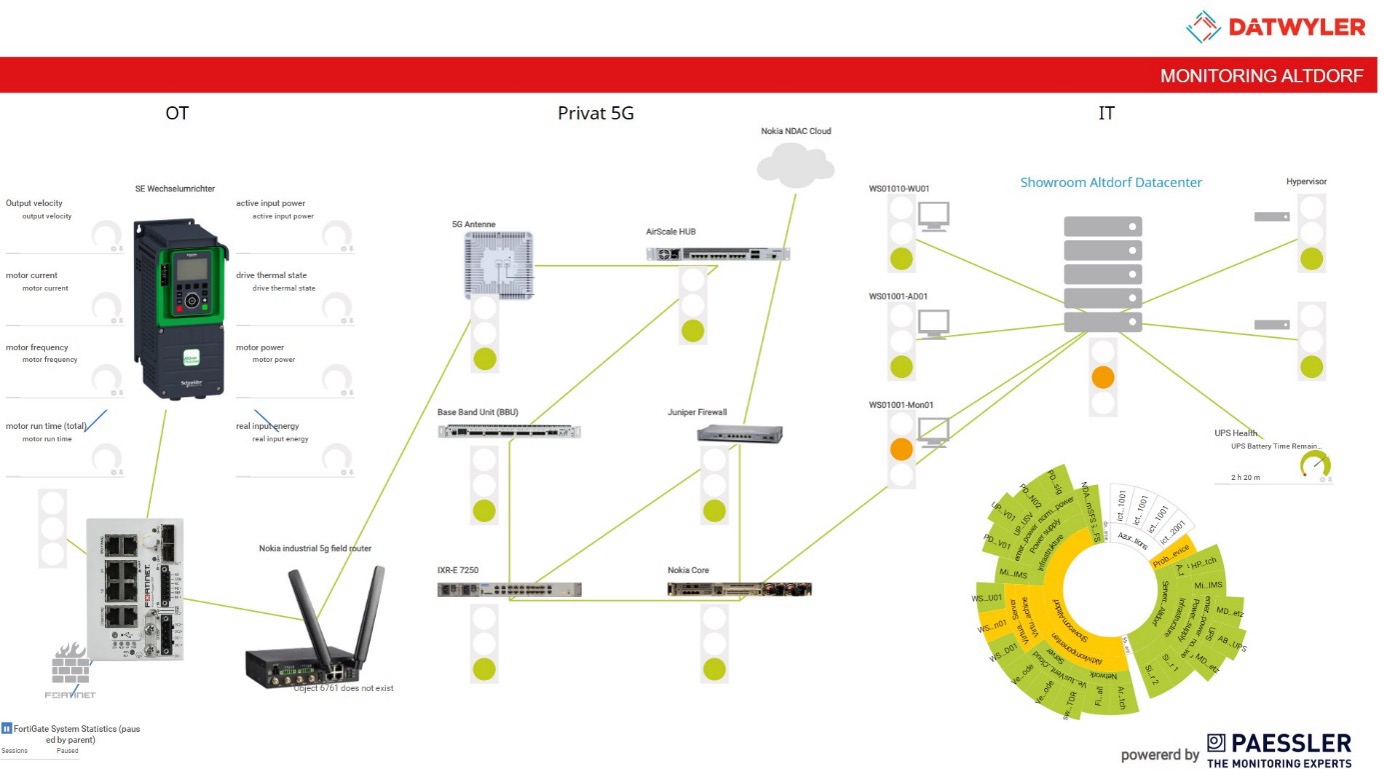

While newly designed industrial plants often come fully wired and networked, digitalizing existing facilities requires alternative data transmission methods. 5G networks represent one such option utilized by Dätwyler. The critical factor is having all components monitored through a single solution, enabling a comprehensive overview of the entire production process—including the supporting IT environment and OT components. Only this approach allows real-time analysis and correction when malfunctions occur.

Paessler PRTG supports virtually all IT protocols as well as key OT methods such as MQTT, OPC UA, and Modbus, enabling industrial components to be incorporated into higher-level monitoring systems. In their OT environment, Dätwyler specifically uses MQTT Statistic, MQTT Subscription, MQTT Roundtrip, and REST API sensors for monitoring Node Red instances. They also employ Docker container sensors for monitoring Docker containers, SQL sensors, certain SSH status sensors (primarily to retrieve information from Linux servers), and OPC UA Server sensors to access machine data already available in OPC UA servers. This is illustrated below by a Dätwyler showcase for monitoring a converter.

Dätwyler uses PRTG in production for the following monitoring use cases:

- Roll length

- Trigger speed

- Sheathing system and flow

- Outdoor temperature

- Edge devices for data flow

- Gateways

Intelligent monitoring plays a central role in production environments. Dätwyler brings extensive experience in this domain from their own cable manufacturing operations.

For instance, maintaining precise temperature control is critical during the cable sheathing process. Continuous monitoring, combined with long-term data storage and sophisticated data analysis, provides invaluable insights for ongoing optimization of production processes.

“Errors on edge devices typically only become apparent after a delay. With PRTG, we can install a multi-platform probe in a Docker container directly on the edge device. Since then, we've been able to monitor each device virtually in real time and intervene immediately when problems arise.”

Pascal Walther, Head of IT/OT at Dätwyler IT Infra

Stabilizing the edge

Edge computing plays a pivotal role in industrial digitalization. Devices at the OT-IT interface perform dual critical functions: collecting, pre-processing, and forwarding production data from the OT side, while also translating and transmitting control signals and commands from the IT side to OT components.

Bottlenecks or malfunctions in edge devices can potentially halt entire processes. A recent incident at Dätwyler illustrates this vulnerability—they experienced an OPC UA server failure that unfortunately went undetected initially. The server has since been integrated into PRTG monitoring, which enables alert configurations that provide immediate notification when an OPC server failure occurs. Pascal Walther, Head of IT/OT at Dätwyler, explains:

“Errors on edge devices typically only become apparent after a delay. With PRTG, we can install a multi-platform probe in a Docker container directly on the edge device. Since then, we've been able to monitor each device virtually in real time and intervene immediately when problems arise.”

Substantial financial risk from production failures

A hypothetical failure of production facilities can result in considerable financial losses. This can be illustrated through a sample calculation:

A core machine can produce approximately 80 km of cores per hour, which translates to roughly 10 km of finished cable for 4P Runner cables. Such a disruption would represent a revenue loss of several thousand Swiss francs per hour. Dätwyler currently operates three core machines, with two typically running simultaneously. In a worst-case scenario, the failure of both operational systems could quickly lead to five-figure revenue losses per hour. This assessment underscores the necessity for reliable and continuous monitoring of production systems to detect potential failures early and address any issues immediately.

Conclusion

Although Dätwyler IT Infra, as a Swiss company, is not directly subject to EU directives on network and information security, their global service operations with a European focus mean NIS-2 will inevitably play a central role in future projects. Pascal Walther also recognizes significant added value in PRTG in this context:

“Many of our customers are directly affected by NIS-2 and need to take measures to ensure the security and reliability of their systems. Comprehensive and consistent monitoring is one of the key aspects of data security, and Paessler PRTG in particular, with its wide range of applications and numerous customization options, is an ideal solution in this context.”

Get to know more happy PRTG customers

Customer success story Lord Wandsworth College & PRTG

PRTG has been integral in shifting Lord Wandsworth College's ticketing away from a system where users report issues towards a proactive approach. ➤ Read the complete customer success story now!

Customer success story School District of Pickens County & PRTG

During the pandemic, PRTG helped keep the IT staff, students, and teachers on the same page even if they had to work remotely. ➤ Read the complete customer success story now!

Customer success story Tri-County Technical College & PRTG

Many TCTC faculty members run web-based applications, including administering online tests and exams to their students, which PRTG helps to monitor. ➤ Read the complete customer success story now!